Ensure Freshness and Quality from Farm to Doorstep with

Our IoT-Enabled Bulk Milk Chiller

SMART BULK MILK CHILLER WITH ADVANCED TECHNOLOGY TO REVOLUTIONISE MILK STORAGE AND PRESERVATION. THIS INNOVATIVE TECHNOLOGY ALLOWS US TO RAPIDLY CHILL OUR MILK TO THE OPTIMAL TEMPERATURE, PRESERVING ITS FRESHNESS AND NUTRITIONAL VALUE. OUR MILK IS SOURCED FROM LOCAL FARMS AND PROCESSED IN THE MOST HYGIENIC AND QUALITY-CONTROLLED ENVIRONMENT, ENSURING THE HIGHEST STANDARDS OF QUALITY AND HYGIENE. EXPERIENCE THE FUTURE OF DAIRY FARMING WITH THE SMART BULK MILK CHILLER, AND TAKE YOUR MILK QUALITY, EFFICIENCY, AND PROFITS TO NEW HEIGHTS.

IoT Connectivity:

Elevate Dairy Management

- Key Connector, Stay Informed: Utilize IoT-enabled Bulk Milk Coolers (BMC) to manage your dairy business anytime, ensuring seamless management and improved efficiency.

Sensor Integration:

Precision Perfected

- Sensor Intelligence: Integrated advanced sensors to access monitoring of milk parameters, storage conditions and maintaining high standards every time.

Data Analytics and Automation:

Empowering Efficiency

- Data-Driven Automation: Leverage data analytics to drive automation and enable smart decision-making for plant operations, ensuring optimal performance.

Organic Process Management:

Ensuring Adherence

- Process Adherence in the Farms: Proactively monitor and manage follow-up processes, maintaining standard operating practices and procedures, maximizing high standards of organic farming.

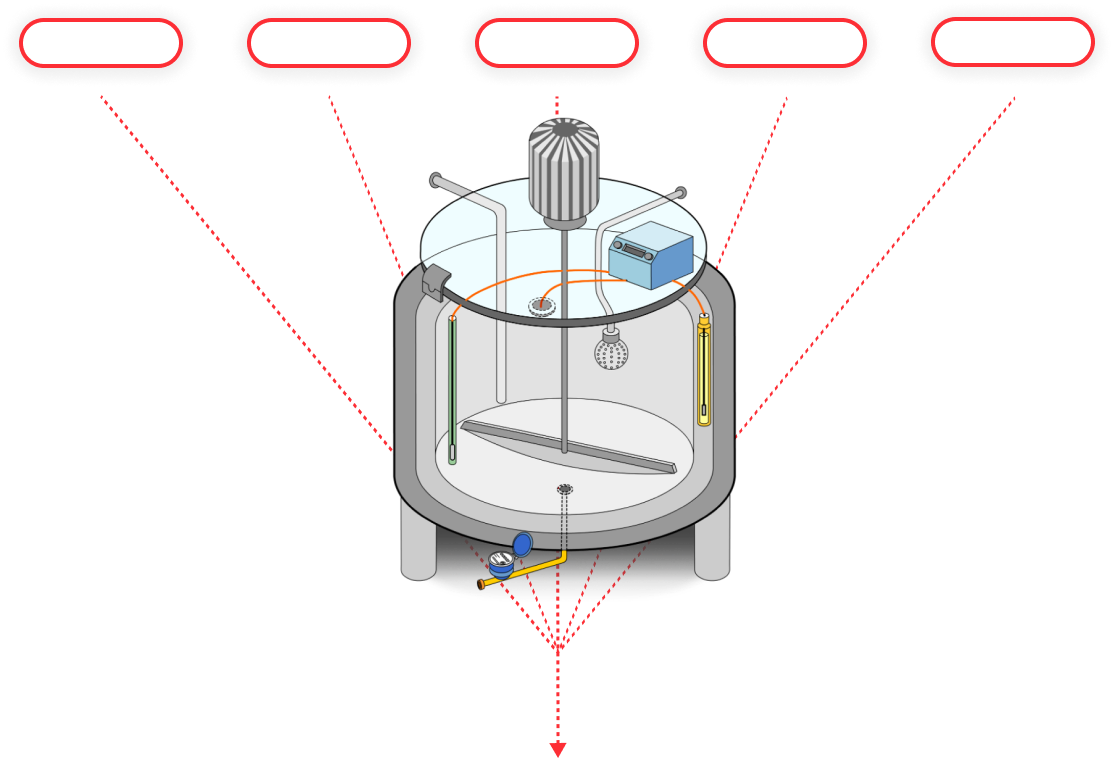

KEY FEATURES

By Integrating These Features, We Aim To Provide A Comprehensive And Efficient Milk Management System That Enhances Productivity, Quality, And Operational Efficiency.

Centrally Monitored System

Maintains desired temperature range, power agitation, and cleanliness. Ensures effective sterilisation cycles and adherence to standards. Monitors key parameters such as milk, glycol, and ambient temperature; lid open/close status; milk level and flow; stirrer and compressor status; power consumption; and humidity levels.

IoT Insight System

Provides real-time insights on chiller status via mobile devices for supervision, aiding in efficient monitoring and management.

Mobile Monitoring through Smart App Interface

Offers real-time updates and remote access for supervisors, enhancing efficiency and oversight.

Cloud Command

Enables remote access and control, sending alerts, and tracking performance.

Integration with Milk Parlour

Ensures efficient milk transfer and compatibility with existing infrastructure.

Agitator Function

Maintains milk homogeneity and prevents cream separation.

Milk Dispatch Preparation

Prepare milk efficiently for dispatch.

Eco Saver Technology

IoT-enabled system that optimises operational costs by efficiently managing the machine's power consumption.

Data/Vision Analytics

Centralised monitoring and analysis system designed to ensure optimal milk quality.

HOW IT WORKS?

Sensors Collect Various Data Points

Data Is Transmitted Via GPRS To The Cloud

.png)

The Life9 Cloud Processes And Anayses The Data

.png)

Real-Time Analytics Are Displayed On A Dashboard For Monitoring And Decision-Making.